Why Mikrosam

35 years in business,

4+ decades know-how

Customer-focused

engineering

45+ countries

Many industry-firsts

and patented solutions

Engineered-to-order Machines, Automated Solutions & Software

24/7 Global Support

Our Products

Explore our full range of world-class Filament Winding equipment

Modular, Upgradeable and Reconfigurable AFP and ATL Systems

Mikrosam is a leading provider of Factory Automation for composite manufacturing.

- World-leader in Automated Lines for CNG, Hydrogen and LPG tanks

- Curing Ovens, Extractors, Automated Handling and Inspection Systems

- Automated Thermoplastic Composite Parts Production

TowPreg and Prepreg Production Equipment

Slitting and Conversion of Composite Prepregs

We offer Training, Prototyping, Testing, and other services for your advanced composites needs

- Training on advanced composite manufacturing

- Analysis and simulation of winding and layup technologies

- Prototyping services for advanced composite using AFP/ATL or FW

- Development of mandrels and trials

- Proof-of-Concept production testing using advanced composites

Our Software

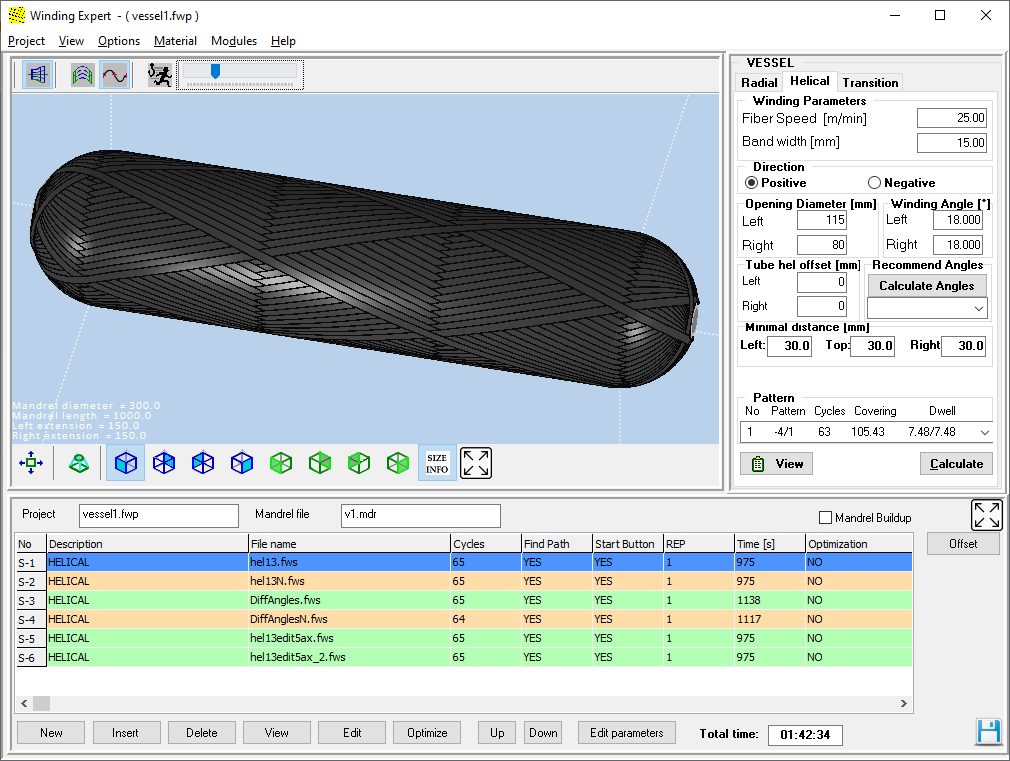

Software for Offline Analysis, Programming and Simulation for Filament Winding

- Mandrel generation

- Winding pattern development

- Geodesic and non-geodesic winding path development

- Winding path and pattern simulation

- Post-processing

- Control data generation

Modern NURBS platform for simulation and programing of AFP & ATL machines

- CATIA Compatible

- Import/Export to standard formats such as IGES, STEP, NASTRAN, SolidWorks, etc.

- Generates layup on mandrel shapes

- Sophisticated layup algorithms and attributes

- Organization of plies and courses

- Analysis of layup and many more feature

Continuous improvement via data monitoring and traceability

- Comprehensive and Custom Quality Control System for Online and Offline Tracking and Reporting of CompositeManufacturing

- Data Acquisition and data management hardware & software

- Product & Program data, Raw material consumption, Operation and process time

- Process speed, temperature, Compaction pressure, Tension monitoring

- History data for every manufactured part

- Possibility to include additional data on customer request.

News & Events

Mikrosam will showcase its latest developments in affordable Automated Fiber Placement (AFP) and in-house prepreg slitting and rewinding technologies at JEC World 2026. Visitors can…

We are proud to announce that Mikrosam has been awarded the esteemed "3rd November" award for 2025 by the Municipality of Prilep. This distinguished award…

Mikrosam’s participation at the Western Balkans Human Capital Days in Tirana showcased Macedonia’s leadership in advanced automation and skills development for the future workforce. On…

28.09.2025

This Saturday, September 27, Prilep hosted a special celebration marking two major anniversaries – 16 years since the founding of the Institute for Advanced Composites…

Stefani Nedelkova Kuzmanoska - Marketing & PR Manager Vele Samak - Chief Revenue Officer In the fast-evolving world of composite manufacturing, automation is no longer…

28.07.2025

Visit Mikrosam at the Hydrogen Technology Expo - the world’s largest suppliers trade fair for hydrogen technologies, materials, components, and engineering solutions. Meet our team…

Careers

Our engineering-driven culture has excellent opportunities for people looking to drive the next generation of automated manufacturing, software and solutions. Together with our in-house production we provide ample training and education opportunities.

Academy

Mikrosam Academy is open for talented people interested in exploring the areas of computer programming and design, skilled engineering assistants, R&D support and more.

ENG

ENG